Lihlahisoa

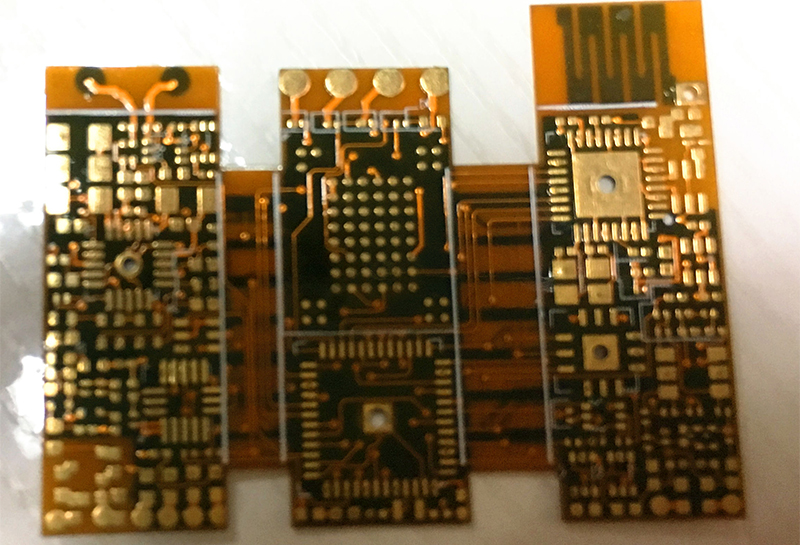

4 Layer FPC e nang le fr4 stiffener ka sistimi ea mojule ea 4g

| Likarolo | Likarolo tse 4 li fetoha |

| Botenya ba boto | 0.2mm |

| Lintho tse bonahalang | Polymide |

| Botenya ba copper | 1 oz (35um) |

| Qetellong | Enig au tenk ea 1um; Ni botena 1 |

| Hole (limilimithara) | 0.23mmmm |

| Bophara ba mohala oa mohala (mm) | 0.15mmm |

| Mehala ea mehala (mm) | 0.15mmm |

| Leske ea Maske | Botala |

| 'Mala oa Legend | Tšoeu |

| Ts'ebetso ea Mehani | V-scoring, CNC ea cnc ea (routing) |

| Packing | Mokotla oa anti-Static |

| Teko ea e-mail | Probe e fofang kapa fixture |

| Maemo a amohelehang | IPC-A-600h Class 2 |

| Kopo | Li-elektroniki tsa likoloi |

Kenyelletso

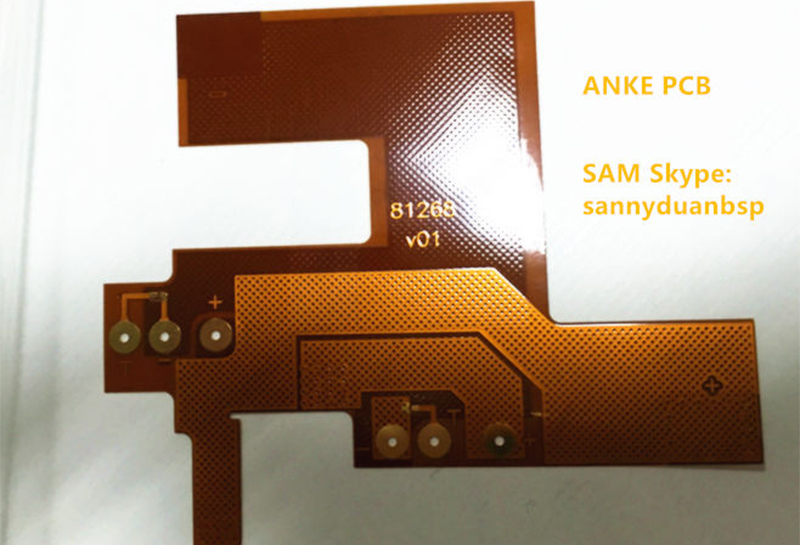

CCB ea Flex ke mokhoa o ikhethang oa pcb eo u ka e khumame. Hangata li sebelisoa bakeng sa letsoalo le phahameng le ts'ebetso e phahameng ea mocheso.

Ka lebaka la ho hanyetsa hantle ea mocheso, boqapi bo feto-fetoha le maemo bo hlile bo loketse likarolo tse ngata tse ntseng li eketseha. Filimi ea polyester ea Polyester e sebelisitsoeng ho aha merero ea Flex e sebetsa e le thepa e ka tlaase.

U ka fetola botenya ba koporo e tsoang ho 0.0001 "ho isa ho 0.010", ha thepa ea puo e ka ba lipakeng tsa 0.0005 "le 0.010" e le boima. Metlae e 'maloa e hokahana le moralo o feto-fetohang.

Ka hona, ho na le likhokahano tse fokolang tse anngoeng. Ntle le moo, lipotoloho tsena li nka feela 10% ea sebaka sa boto ea Rigid

ka lebaka la kopano ea bona e felisang.

Lintho tse bonahalang

Ho sebelisoa lisebelisoa tse feto-fetohang le tse ka bonoang ho iketsetsa li-PCB tse feto-fetohang. Ho feto-fetoha ha eona ho e lumella hore e fetohe kapa ho sisinyeha ntle le tšenyo e ke keng ea fetoloa ea likarolo kapa likhokelo.

Karolo e 'ngoe le e' ngoe ea PCB ea Flex e tlameha ho sebetsa hammoho ho atleha. U tla hloka lisebelisoa tse fapaneng hore li bokelle boto ea flex.

KELETSO EA BUKA

Mokhoa oa mokhanni oa khatiso le ho lekola bo-ramahlante monahano ea substrate le filimi. Ho feta moo, substrate e tlameha ho khoesoa le ho curl.

Polyimide le lishiti tsa polyester li sebelisoa hangata ho lipotoloho tse feto-fetohang. Tsena ke tse 'maloa feela tsa lifilimi tseo u ka' nang eaba u li fumana, empa ho na le tse ling tse ngata tseo u ka khethang ho tsona.

Ke khetho e ntle ka lebaka la litšenyehelo tse tlase le substrate e phahameng ea boleng.

Pi Polyimide ke lintho tse sebelisoang haholo ka Baeti. Mofuta ona oa polokelo ea puso o teng o ka thibela litheko tse matla. Kahoo ho qhibiliha ha se bothata. Kamora hore e phunya boikhathollo bo khathollang, e ntse e boloka maemo a hae a ho fetoha le ho fetoha le maemo. Ntle le sena, e na le thepa e ntle ea motlakase.

Mokhanni oa mokhanni oa khatiso

U tlameha ho khetha ntho ea mokhanni e fetisang matla ka ho sebetsa hantle haholo. Hoo e batlang e le lipotoloho tsohle tsa bopaki bo phatlohang ho sebelisa koporo e le mokhanni oa mantlha.

Ntle le ho ba mokhanni oa mokhathala haholo, koporo le eona e bonolo ho fumana. Bapisoa le theko ea thepa e 'ngoe ea khato, koporo ke theko ea thepa. Ho fana ka boitšoaro ha hoa lekana ho senya mocheso ka nepo; Hape e tlameha ho ba mokhanni ea motle oa ho futhumatsa. Ho ka etsoa lipotoloho tse feto-fetohang tse ka sebelisang thepa e fokolisang mocheso eo ba e hlahisang.

Makhoaba

Ho na le khokahano lipakeng tsa leqephe la polemimeide le koporo ho boto ea potoloho ea Flex. Epoxy le Acrylic ke likhato tse peli tsa mantlha tseo u ka li sebelisang.

Lipehelo tse matla li hlokahala ho sebetsana le lithemparetjha tse phahameng tse hlahisoang ke koporo.