Lisebelisoa tsa Kopano ea PCB

ANK PCB e fana ka khetho e kholo ea lisebelisoa tsa SMT Ho kenyelletsa bukana ea Bochabela, khetha

Ka PCB eo re utloisisang boleng ka botlalo ke eona sepheo sa mantlha sa kopano ea PCB 'me re khona ho etsa setsi sa' mele se tsamaisang marang-rang le ka morao.

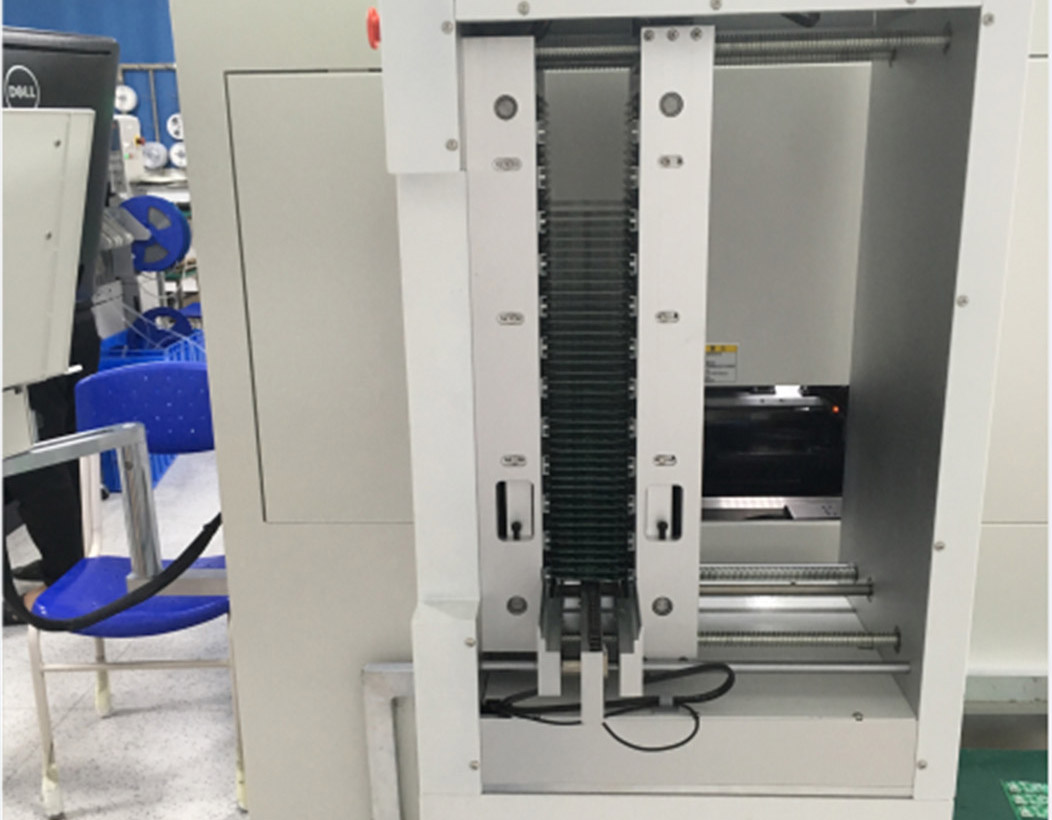

Moroalo oa PCB

Mochine ona o lumella liboto tsa PCB ho fepa mochini oa khatiso oa li-doste.

Monyetla

• Nako ea ho boloka matla bakeng sa matla a basebetsi

• Ho boloka litšenyehelo ho tlhahiso ea Kopano

• Ho fokotsa molato o tla bakoa ke bukana

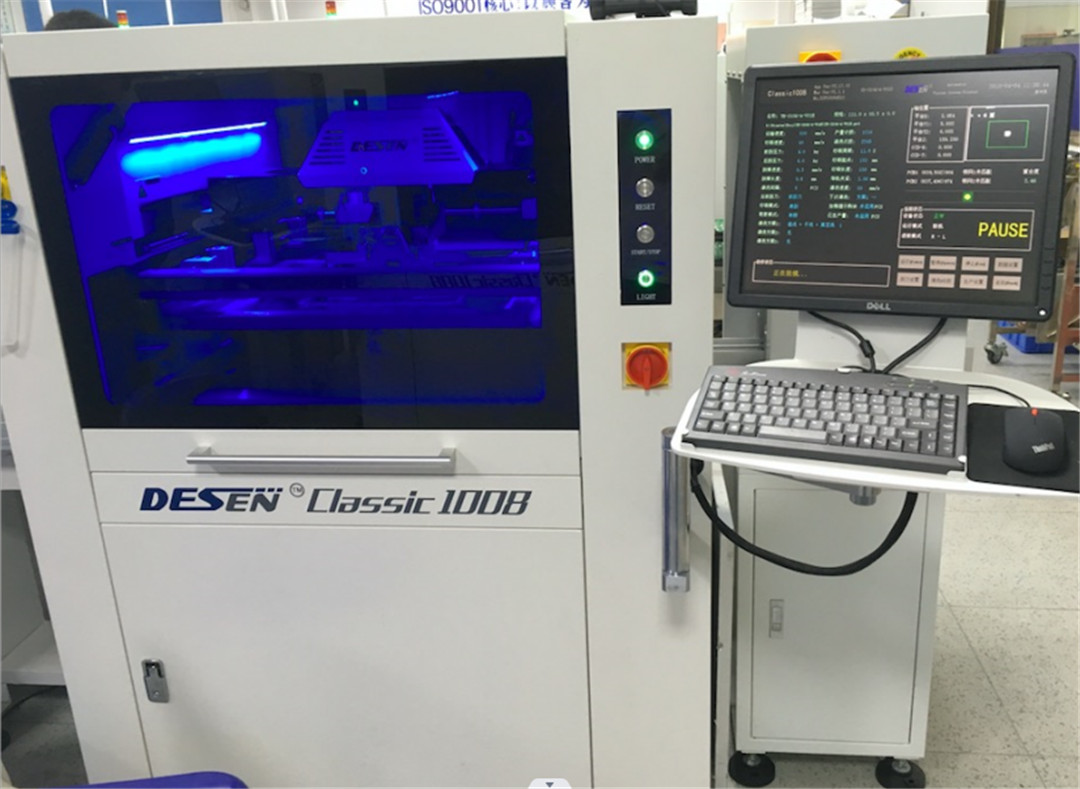

Mochini oa lindclecle o ikemetseng

Any e na le lisebelisoa tsa khale tse kang mochini oa khatiso o ikemetseng.

• Tumitiamable

• Sistimi ea Squeegee

• Sistimi ea Boemo ba Athomake

• Sistimi e ikemetseng

• Phetiso ea PCB le sistimi ea boemo

• Ho tloaelana le ho sebelisana le batho ba bonolo ho tloaela

• Sistimi ea kahale ea setšoantšo

• 2D tlhahlobo le spc

• Align ea CCD Stencenment

• Phetoho ea botenya ba PB e ikemetseng

SMT ea ho khetha

• Ho nepahala ho phahameng le ho feto-fetoha le maemo

• Sistimi ea meneong ea meneo e sa sebetseng hantle ea ho phekola le ho tsitsa

• Sistimi ea Ts'ebetso ea Smart e fana ka tlhahlobo ea maemo a ikemetseng ea boitšoaro, karolo ea boiketsetso ea boiketsetso

• Ehlile e loketse tlhahiso e nyane ea ho ntlafatsa le e mahareng

• Mokhatlo oa Cognex Alignment "Fono e Nohle"

• Sisteme e ka tlase ea Alignment ea Alignment ea Pit Pit Pitp & BGA

• Tsamaiso ea khamera e hahiloeng ka ho ithuta ka mokhoa o hlakileng

• Sisteme ea ho qholotsa

• Litlhahlobo tsa pono pele le kamora tlhahiso

• Ho sokoloha hohle

• Sekhahla sa ho beha: 10 500 CPH (iPC 9850)

• Litsamaiso tsa bolo ea bolo ho x- le Y-axes

• E loketse phepo e sa tloaelehang ea Auto ea 160

TLHOKOMELISO E PHETHANG EA PUSELETSO EA DRATLO / PUSELETSO MAHALA

• Software ea ts'ebetso ea Windows XP e nang le mefuta e meng ea Machaena le Senyesemane. Sistimi eohle tlasa

Taolo ea ho hokahana e ka sekaseka le ho bonts'a ho hloleha. Lintlha tsohle tsa tlhahiso li ka bolokoa ka botlalo 'me li hlahlojoe.

• PC le setjha se laolang sethunya se nang le ts'ebetso e tsitsitseng; Khopolo-taba e phahameng ea ho pheta-pheta ha profaisi e ka qoba tahlehelo ea lihlahisoa e hlahisitsoeng ke ho matha ha khomphutha e sa tloaelehang ea komporo.

Moralo o ikhethang oa ho kopanya se futhumatsang ha libaka tse futhumatsang ho tloha mahlakore a 4 a fana ka katleho e phahameng ea mocheso; phapang e phahameng ea mocheso pakeng tsa libaka tse peli tse kopaneng li ka qoba ho kenella ha mocheso; E ka khutsufatsa phapano lipakeng tsa mocheso o moholo le likarolo tse nyane 'me u kopane le tlhoko ea theko ea pcB e rarahaneng.

• Ho futhumatsa moea ho futhumatsa moea kapa ho futhumatsa metsi ka mokhoa o pholileng ho tsamaisa mefuta eohle e fapaneng ea borena ba sepolesa sa mahala.

• Ho sebelisa motlakase ka tlase (8-10 kwh / hora) ho boloka litšenyehelo tsa tlhahiso.

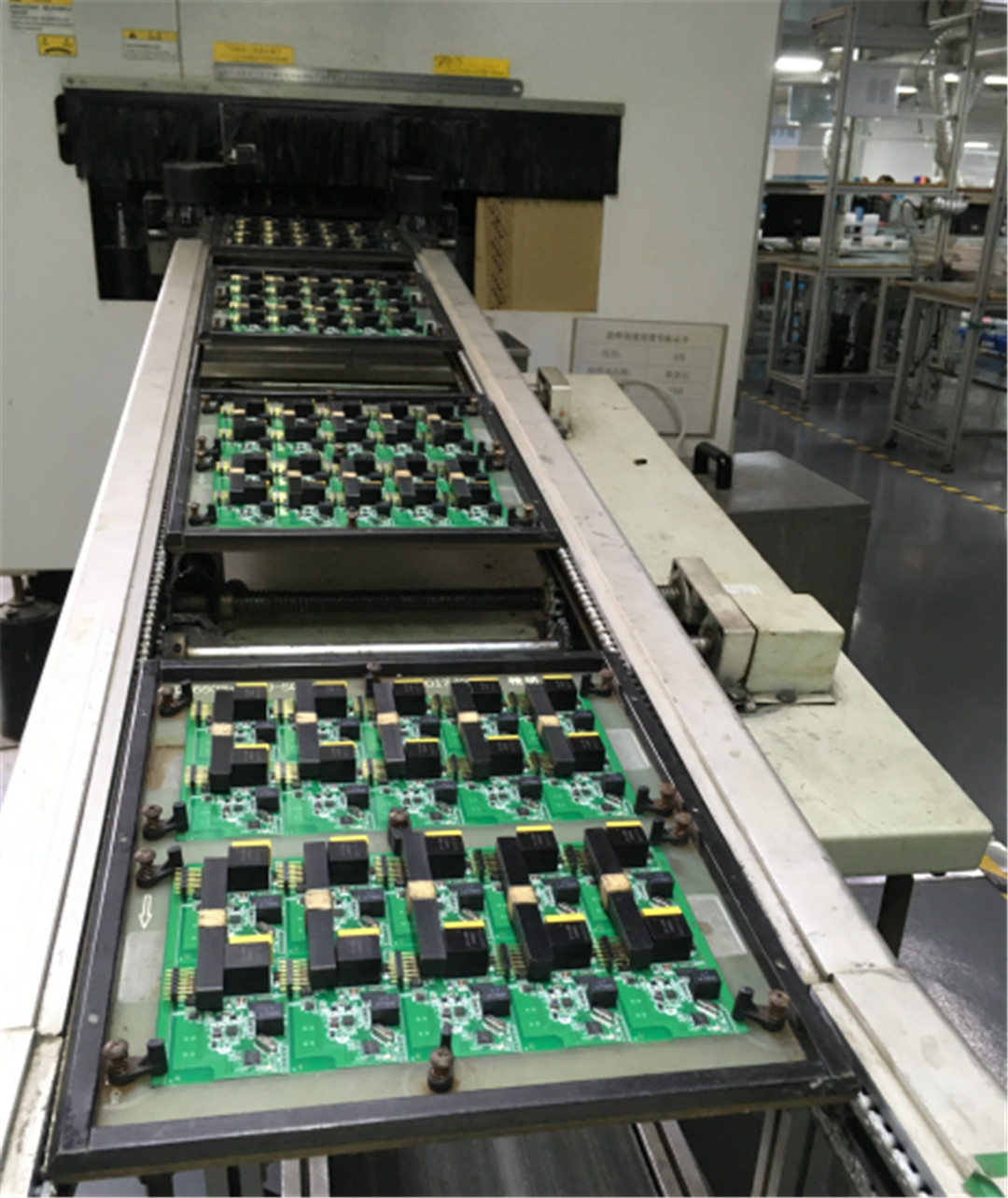

Aoi (e ikemetseng e iketsahallang

Aoi ke sesebelisoa se tseba bofokoli bo tloaelehileng ba tlhahiso e ngata ho latela melao-motheo ea mahlo. Aol ke mahlale a tsoang libakeng tse tsoang, empa o nts'etsapele ka potlako, 'me baetsi ba bangata ba hlahisitse lisebelisoa tsa ALS liteko.

Nakong ea tlhahlobo ea othomathike, mochini o fana ka ka botsitso ka hanyane ka hanyane, 'me o pata litšoantšo,' me o bapisa le moholi o fumanoeng e le likarolo tse tšoanelehang ka har'a database. Lokisa litokiso.

Lebelo le lebelo, ho sebetsa ka mokhoa o hlakileng ho bona liphoso tse fapaneng tsa ho beoa le bosholu ba PB.

PC Boards e tsoa libakeng tse phahameng tsa bophahamo bo phahameng ho liboto tse tlase tse boholo, tse fanang ka maikutlo a tlhahlobo ea tlhahlobo le ho ntlafatsa boleng ba tlhahiso le boleng.

Ka ho sebelisa Aol e le sesebelisoa sa phofo ea phokotso le liphoso li ka fumanoa le ho felisoa esale pele ts'ebetsong ea kopano, e bakoloa ke taolo e ntle ea tšebetso. Ho lemoha ha likoli ho tla thibela liboto tse mpe ho tsoa ho romelloa ho fangoana ka mor'a kopano. AI e tla fokotsa litšenyehelo tsa ho lokisa le ho qoba liboto tse tsoang ho eona ntle le ho li lokisa.

3D x-ray

Ka kotlo e potlakileng ea theknoloji ea elektroniki, e leng kopano ea letsoalo le tsoelang pele ea mekhoa e mengata e mecha ea liphutheloana, litlhoko tsa boleng ba kopano ea potoloho li ntse li phahama ebile li phahame.

Ka hona, litlhokahalo tse phahameng li beoa mekhoa ea ho fumana le mahlale a ho fumanoa.

Bakeng sa ho fihlela tlhoko ena ena, mahlale a makgetlo a macha a tlhahlobo a lula a hlaha, 'me theknoloji ea tlhahlobo ea 3 e othomaneng ke moemeli ea tloaelehileng.

E ke ke ea sheba feela moholi o sa bonahaleng oa lesapo le hlakileng, joalo ka lihlahisoa tsa li-grid tsa bolo ea maoto), joalo-joalo tsa sephetho sa ho lemoha ka thata.

Hajoale, mekhoa e mengata e fapaneng ea liteko e sebelisoa tšimong ea tlhahlobo ea likopano ea elektroniki.

Lisebelisoa tse tloaelehileng ke tlhahlobo ea bonngoe (MVI), Tester ea potoloho (ICT), 'me u be le ophoka

Tlhahlobo (tlhahlobo ea othomathike). Ai), tlhahlobo ea x-ray e iketsang (axi), tester tester (ft

Seteishene sa Moputso oa Pcba

Ha re ntse u amehile ka hore kopano ea SMP e amehile ka methaana e mengata e kang ho hlomphuoa, ho beha sebaka sa pokello ea pcB, le ho hloekisoa.

1. Ts'ebetso ena ke ho tlosa likarolo tse lokiselitsoeng ho tsoa ho pb ea libapali tse tsitsitseng tsa SMT. Molao-motheo oa mantlha ha o senyehe kapa oa senya likarolo tse tlositsoeng, metsoako e potolohileng le lipara tsa PCB.

2. Karolo e benya: Kamora likarolo tse sebetsang tsa molao lia u hlakoloa, haeba u batla ho tsoela pele ho sebelisa likarolo tse tlositsoeng, u tlameha ho insupents.

3. Ho hloeka ha pcb pad: Ho hloekisa pcb pad ho kenyelletsa mosebetsi oa ho hloekisa le ho hokahana. Boemo ba pad hangata bo bua ka ho lekanya ka mokhoa oa pcb oa sesebelisoa se tlositsoeng. Ho hloekisa pad hangata ho sebelisa lesole

Sesebelisoa sa ho hloekisa, joalo ka tšepe ea sepolesa, e tlosa lesole le setseng marakeng, ka nako e telele ea ho tlosa likotlo tse feletseng kapa litsietsi tsa feshene.

4. Ho beoa ha likarolo: Lekola PCB e sebetsang e sebetsang le lesole le hatisitsoeng le hatisitsoeng; Sebelisa sesebelisoa sa karolo ea karolo ea seteishene sa Rework ho khetha nozzle e loketseng 'me u lokise PCB ea ho reoa.

5. TLHOKOMELISO: Mohlokomeli oa sepolesa bakeng sa Rewena o ka aroloa ka har'a theko ea matsoho le ho khothaletsa sefuba. E hloka ho nahanela ka hloko ka thepa ea motsoako le PB ea Layout, hammoho le thepa ea boitsebiso bo sebelisoang. Metsoako ea lipina e bonolo e bonolo ebile e sebelisoa haholo ke ho nchafatsa ho nchafatsa likarolo tse nyane.

Mochini oa Tlhaho ea Phahameng oa Privel

• Ho ama skrineng + ho laola sefahleho sa PLC, ts'ebetso e bonolo le e tšepahalang.

• Moralo o hlophisitsoeng o hlophisitsoeng o hlophisitsoeng, moralo oa motsoako oa kahare, eseng o motle haholo empa ho bonolo ho o hlokomela.

• Flux Srayer e hlahisa atomination e ntle ka tšebeliso e tlase ea flux.

• TOB E FANELA HO FIHLA MOTSI OA MOTSOALLE HO TLOTLISANG HO THUSA MAHALA Trufo ea Atomisi e Fihlanngoeng Setereke se Pholohileng, se netefatsa ts'ebetso e sireletsehileng.

• Ntho e purui e matlafatsang e ntse e loketse e loketse bakeng sa tokiso; PUD Lits'ebetso tsa taolo ea PROD, mocheso o matla, o boreleli, rarolla bothata ba ho etella pele.

• Lereki le sebelisa matla a phahameng, eseng sebopeho se sa rarollotsoeng la boomablection se hlahisang mokhoa o phahameng oa tšepe.

• Li-nozzles tse entsoeng ka Titanium li netefatsa hore ho na le mafura a tlase le oxidation e tlase.

• E na le ts'ebetso ea qalo ea nako ea nakoana le ho koala mochini kaofela.

Nako ea poso: Sep-05-2022